January 2012

3D Cabinet design + Optimisation

For may companies that own CNC Equipment our Polyboard design software

represents extremely good value, both for companies with older PTP CNC

machines and the increasingly popular flat table nesting machines.

However Polyboard does come in multiple versions, with the CNC version

being the highest level. What this means is that for companies that do not use

CNC machines they have the choice of two lower versions of Polyboard that

are cheaper in price but do not sacrifice design capability.

For companies that are looking at the these lower versions would typically be

looking at software that will meet their design needs,. i.e. being able to design

and create their own furniture and cabinets in the way that they want. Many

software systems are purely based on pre-created libraries of cabinets,

whereas all versions of Polyboard allow you to design cabinets the way you

make them. All versions provide an automatic cutting list, and Polyboard is a

purely 3D based design system. So not only are you able to generate 3D

Drawings and rendering of your cabinets and rooms, but even when designing

your cabinets from scratch it is done in a 3D environment so you can see

clearly what you are doing.

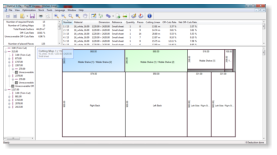

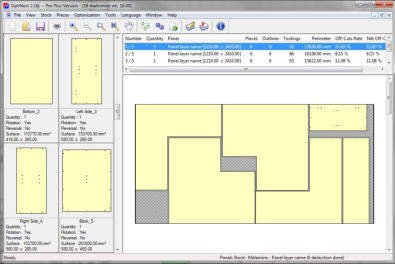

As we explained in detail last month, the decision to use optimisation is really

clear: if you cut your parts on a panel or Beam saw, and you are already geting

your cutting list automatically generated from design software, you should be

using sheet optimisation software. As we mentioned, The connection is

seamless between Our design software Polyboard and our optimisation

Opticut. Its simply a matter of a couple of click and you have optimised all your

parts and because Opticut is a Multi-format program it will optimise all the

different materials in your job at once and in a few moments you know exactly

how many sheets you need what your waste will be and ready to go cutting

layouts ready to be cut.

To start off the new your we are offering great discounts on orders for

Polyboard + Opticut software packages. this represent good savings off our

already good value products. To receive this discount please contact us, and

mention you read this article.

Contact Us: 0411 969 437

Software News Blog

News, Opinions and Helpful tips from our software experiences

Send us your feedback!

Please use the form below to let us know what you thought of

these articles. We aim to include more varied topics so if you

could suggest ideas it would be great to hear from you.

Opticut Panel optimisation

Polyboard Cabinet Design

February 2012

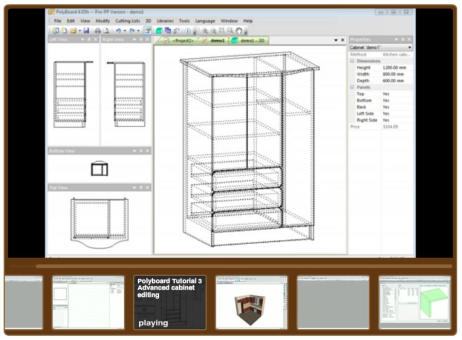

New Tutorial Videos and Trial

Downloads

As you may have noticed we have added a new

videos page to our website. We have begun by

adding basic and then more advanced videos on

our cabinet design software Polyboard. Over the

next coming months we will progressively be

adding more videos.

Although we provide excellent training services

for our customers at reasonable rates, we have

had requests for additional training material to be

provided, and in addition to supplementing our

one on one training services these videos also

provide an opportunity for customers who are

located at a distance from our office to get a

good feel for the software.

If you have taken advantage of our free demo

download of the software please take the time to

view some of these videos so that you can get

the most out of your trial and also pick up some

good pointers in using the design aspects. Although our software is designed to be very easy to use, a first time user may be a little

lost, or not know exactly where to get started, so these videos will be very useful to them. The actual demo versions of our software

are not limited in terms of design. You can create and save complete cabinets and have access to all design related features. They

only restrict you in terms of output. As you cannot export cut-lists or CNC files and cannot print reports. If you would like to test the

output of the software please feel free to email me your test design and I can send you back the sample output from Polyboard for

your confirmation and testing.

Over time we will be adding more videos and both of Polyboard and our other software products, and of course if there is a particular

video you would like us to create or are still unsure about any aspect of our software please don’t hesitate to Call or send an email to

us.

September 2012

New Online Store

We are pleased to announce the formation of our

new online store: Officebuilt online ordering. The

new sore will provide easy access to our software

versions and pricing as well as a safe and secure

way of ordering our products on-line. at the

moment software products can be ordered via

Paypal express checkout or you have the option of

checking out with the bank deposit option and

whereby we will send you an invoice for your total.

We are progressively adding our range of software

products to the on-line catalogue. In addition to

our paid versions there is also free trial versions

that customers are free to create an on-line

account, order a free version and proceed to the

download area for the trial download.

The on-line store also allows the ability to share

our products amongst the social networking sites,

and recommend them to friends and associates, as

well as also the built in ability to write reviews on

our products.

July 2012

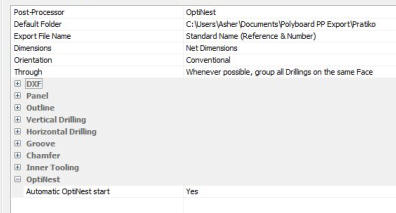

Polyboard to Optinest seamless transfer complete

This month we have completed the requirements

necessary for a seamless transfer from Polyboard to

Optinest. As you may know Optinest is a true shape

nesting package that has a very competent calculation

algorithm (Calculation method) which results in a very tight

nest and maximum material savings. In doing so Optinest

has been added to the list of post-processors in Polyboard

and upon exporting a cabinet or an entire project the parts

list is automatically loaded inside Optinest. From here it’s

just a few clicks away from nesting your parts and

producing dxf files, of the nested sheets.

For a complete nesting package we can now offer

Polyboard - Optinest - Pratiko with Gcode generation for

any cnc machine. However many machines with proper

setup can take the dxf files from Optinest directly and run

them. If you are using nesting software why not take

Optinest for a test drive and be surprised how much

material it can save you over your current nesting software.

December 2012

New or used CNC machine?

An interesting difference between the Australian woodworking industry and our overseas counterparts is the size of our workshops.

Throughout our major capital cites and regional areas its not uncommon to walk into 2-3 man workshops that specialise in custom made

joinery. This is of course partly due to the nature of the market, as Australians traditionally favour custom built in joinery such as kitchens

and wardrobes rather than off the shelf standard modular units. This type of heavily geared custom design market of course lends itself to

small workshop manufacturing as these tend to be more flexible to be able to cater for such demand. In contrast many markets overseas

are dominated by standard product lines which will lend itself to mass production more easily and hence the industry would tend to evolve

into a smaller number of larger companies producing standard joinery products. So the result is we have a very high number of small

companies producing custom joinery.

The other interesting aspect is the rate of take-up of technology. One only has to look at the take-up of first mobile phone and now smart

phones to see how Australians love their technology. The woodworking industry is no different CNC machines, in particular the nesting

variety are becoming more and more common even in very in these very small 2-3 person workshops. The benefits of adding a flat be d

nesting machine have been discussed many times, despite the cost when a company considers the increased production, accuracy and

flexibility and reduction in labour and material costs the benefits are hard to ignore. Particularly the ability to take on difficult to machine

jobs such as curved work without reservation is also a major advantage.

Its not surprising that given that the machinery sales people have made

sure that industry is well informed about the benefits of nesting

machinery, many of the companies that we meet have a plan to introduce

a nesting machine into their workshop as soon as they can afford it.

Often this is a bit premature as these companies sometimes are not even

using any sort of design software. Cabinetmakers that are new to the

CNC world should be aware that acquiring a machine is one thing but to

get maximum benefit from the machine investment needs to be software

in place to program it. It should be pointed out that the software should

be capable of empowering the user to be as creative as they wish and

manufacture any product within the capabilities of the machine not just

within the limitations of a particular software package, but more on this

subject in another article.

However when the company gets to the stage of being ready to order a

new CNC the next question is of course new or second hand? This is

only really a question that can be considered now as flat bed nesting

machines have only been available for approximately the last 10 years, and as such have not been available in reasonable numbers until

recently. A search on the website machines4u.com.au at the time of writing showed approx 40 used flat bed nesting machines available for

sale Australia wide. ranging from about $25,000 to 80,000 in price. Having this many to choose from really makes a used machine a

serious proposition. when you consider that a brand new base model machine will start at about 70,000 with a very basic features and

questionable build quality level. to get something with moderate features will be well over 100k mark and certainly a machine with all the

bells and whistles and a impeccable built quality will often push the 200k mark.

Clearly then a used machine wins on price. But what about the reliability of a used machine? but here is the interesting part in psychology

many people will not concern themselves with buying a used car particularly when its only a couple of years old, but when it comes to

purchasing a used CNC they shake their heads, and only look at a new machine. The truth is buying a used CNC is no different A used

machine provided it hasn’t been worked continuously around the clock is likely to be just as reliable. If you also consider that for the same

or less money as a low end new machine, you can get a high end used and get advanced features such as auto unloading, offloading or

both and a large drill bank, any two of these features will set the company way ahead in terms of productivity compared to the low end new

machine without these features.

Another interesting comparison is when you look at the other end of the used market. at the cheapest end you have the older machines

such as Chinese single spindle machines and early model ( early 2000’s) European made machines. While the Chinese machines probably

should be avoided, the European machines might be worth a look at if your budget only extends this far. As a genuine European machine

will have a very good build quality. It would have been very well specified when compared to a current base model machine that is sold

nowadays. Just like in our own industry our products are designed and simulated on computer before being manufactured machinery is no

different. When an Engineer designs a new machine using simulation software they can accurately predict how the machine (or parts of it)

will behave under various loads. This enables them to design parts with a minimum thickness corresponding to the envisaged usage and

thereby allows the company selling the machine to achieve a lowest cost price-point possible. This is great except when an unexpected

load occurs (a small bump of a pack with a forklift) or even cutting material at a speed or depth or combination of these factors that it was

not designed for, then the machine parts can start to warp or bend.

This is the worst thing that can to happen to a CNC. Remember

one of the primary reasons a company goes for a CNC machine

is to improve accuracy so if something like this occurs outside the

new warranty period the cheap machine will become very

expensive. In contrast buying a used machine that was a high

end model in its day will be a far cry and much better built that

any new cheap machine. But what about the electrical side? Its

important to remember the likelihood of electrical part failure just

statistics, you can have a 10 year old machine with all original

parts, and you could also have a machine that you bought new

just a couple of years ago (according to Murphy’s law usually just

outside the warranty period) will start having axis drive failures,

various power supply failure etc. So while its true that statistically

the electrical parts will more likely fail as the machine ages,

remember the cost saving right at the beginning will offset future

repair costs. One warning though when dealing with older

machines and computer technology there is the likely chance

parts will become obsolete. so the help mitigate this problem its

important that you select the brand of used machine carefully to

ensure reliable service technicians and spare parts are available.

On the software side while some new machines may come with software of some description bundled, as we mentioned its important that

to get the maximum benefit from your machine the brain which is the software that pilots your machine is the best that it can be. Keeping

this in mind fro ma software perspective it does not matter whether your machine is new or used if you have inefficient software you will be

let down. For example many new machines come with a nesting suite built in but, while it may place some parts together it may not be the

tightest nest. Our own Optinest true shape nesting software out performs many of the machine manufactures bundled software giving you

savings not only in material usage but also in labour as when it comes to nesting if you can save a few sheets by getting as tighter nest you

are also saving the labour in moving these extra sheets and offcuts on and off the machine.

In a follow-up article we we will look at some things to look for when inspecting and purchasing a used machine and maybe do a review of

one ore two popular used nesting machines such as the Biesse Rover 24FT

BLOG | Newsletters | FAQ | Testimonials | Videos | Polyboard | Optinest | Opticut | Wardrobes | Kitchens | Office fitouts | Contact