Contact Us: 0411 969 437

Officebuilt Software News Blog

News, Opinions and Helpful tips from our software experiences

Send us your feedback!

Please use the form below to let us know what you thought of

these articles. We aim to include more varied topics so if you

could suggest ideas it would be great to hear from you.

January 2013

New Industry pages, Testimonials, Newsletter list

Welcome back everyone from your well earned holiday break we hope the new year of 2013 will bring much success to your business

endeavours! We would like to take this opportunity share with our loyal customers and potential clients, some of the new features that

we have been working on towards the end of that year and are implementing starting this month!

First up we are working on new industry specific product pages on our website. Previously all our product information has been

squeezed into one page fro each product. While the product pages does showcase each product very well, due to the vast features list

and intrinsic flexibility many useful features and abilities of each program have not been highlighted sufficiently. to this end we are

endeavouring to dedicate a new page for each industry segment. Starting with built-in wardrobes, and kitchens, we will move on to

office furniture, stand alone home furniture, bathrooms including shower screens ,and vanities, shop fittings, wooden staircases, metal

staircases concrete staircases etc.. Hopefully in time this will really demonstrate the power and flexibility our unique design programs

Polyboard and Stairdesigner. We will also show how our complementary programs Opticut, Optinest, and Pratiko CAM fit into these

industries manufacturing methods.

In addition over the last eighteen months that we have been promoting our range of unique

software solutions we have been contacted by many potential clients and have followed through

to a good number of satisfied customers who use our products daily. In order to show case just

how happy our customers are, we are compiling a testimonials page where we are publishing

the letters and comments we have received from our valued customers. We recently asked

some of our customers to send in a brief letter about their experience with our software.

So to start it off we have two letters so far, one from a long time

customer Doug Patterson from DAP Joinery in Sydney, and the

other from a recent customer Peter Brown from P & S

Furniture in Perth. Doug is a shop-fitter so his cabinets are

anything but standard, a lot of the programs our these are

built on specific cabinet libraries (usually kitchen cabinets)

but not Polyboard. Doug enjoys the ability to create

parametric cabinets any way he needs to. Doug uses

Polyboard to send out all his cabinet parts directly into

Biessenest for cutting and drilling on his cnc Nesting

Machine. Peter Brown is a recent customer with 40 years

of industry experience. When looking for new design

software he was amazed at the how easy and flexible Polyboard is and

at he price it really is a phenomenal product. Peter uses Opticut together with Polyboard for a

seamless one click transfer of parts into cultists optimised on sheets ready yo be cut with his panel

saw. You can read about Peter and Doug’s experience in their own words on the testimonials page. We will

be adding further customer reviews as they come in.

Finally we are also pleased to announce the launch this month of our email monthly newsletter. if you have contacted us over the last

18 months regarding our software products then we have added your email to our newsletter list. if you would like to either subscribe or

unsubscribe to this list you can do so using our new automated system here. In our newsletter we will highlight recent articles from this

blog, new industry pages, and testimonials that have been added over the past month.

February 2013

Focus on Polyboard and Optinest for nesting CNC Owners (Part 1)

Over the last (almost) two years since we started promoting our software range to Australian cabinetmakers and joiners we have

noticed that that among recent adopters of CNC routers for cutting and nested based manufacturing there is a significant trend towards

customers favouring Biesse supplied cnc machines.

From what we can tell part is due to the brand recognition and reputation, but another part is due to Biesse making the entry cost of

CNC lower by supplying together with its machines. Traditionally when a customer was looking at buying a new CNC, in addition of the

machine itself, they also had to consider the additional cost of design software on top of the machine cost. This obviously raises the bar

and makes a bigger entry barrier for smaller companies facing the prospect of large financing loans to get into CNC and the befits to

production that it brings.

Biesse’s answer to this problem was to include for free their own nesting and toolpathing software: Biesseworks / Biessenest and in

addition they put Biesseworks extensive import /export functionality to good use by including a spreadsheet template. Using the excel

spreadsheet provided the user can set up parametrically complete cabinets, while associating parts specified with Biesseworks

machining files and then once its all set-up, the user can use the spreadsheet / Biesseworks software combination to select cabinet

styles, enter dimensions, quantities and run the whole job through to Biessenest where by the parts together with appropriate drilling’s

and routings are all nested and toolpathed ready to to run.

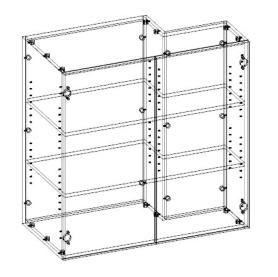

While this solution does get a customer of the ground and into CNC nesting at

relatively low cost, using a spreadsheet as a design application does have many

shortcomings. The first and foremost is the initial set-up time to create cabinet

styles and associated machining part files. Because a separate machining file has

to be drawn for each part in a cabinet it does take considerable time to designs

new style and also because each part is drawn individually there is no easy way of

telling if there are mistakes until a sample cabinet is built and tested. Contrast this

to proper design software where the whole cabinet is shown in 3 dimensions on

screen with all part machining visible to the designer so that they can check in real

time if there are any issues, for example the designer can see immediately if

adjustable shelf holes are too close to the edge of the shelf or the hinges will clash

with a shelf, or even can visually see if there are enough screws or fittings along

the edge of a joint.

For a designer taking into account of these issues are all very difficult if you are

designing a cabinet piece by piece and in addition apart from a few global

variables there is no intrinsic correlation between any two parts. So that if one part

is adjusted all the placement of connecting fittings will most likely move out of

alignment. due to this problem the designer either has a very difficult and stressful

job or he or she will limit the type and complexity of machining operations so that

they can keep onto of them. Contrast this scenario with a designer using a deign

application like Polyboard. where a designer can place hardware and machining

operations that have relationships between parts so much so that adjustment

anywhere on the cabinet will result in the software dynamically updating the part cabinet and part drawing leaving the designer to

concentrate on their job of designing great quality and aesthetically pleasing furniture.

Of course the other features that that a true design application will offer over a spread sheet will be the ability to arrange cabinets

accurately in a 3d space (room) produces rendered 3d views, dimensioned shop drawings of completed jobs, job reports and detailed

cost reports of each job. as well as the ability to create much more complex and detailed cabinets easily with a minimum of fuss.

Polyboard is a full featured design application that will give your designers all these features and more. We have already many

customers who started out on their adventure into the nesting world armed with just a Biesse CNC and the stock supplied spreadsheet

application and subsequently have upgraded their design ability 10 fold by upgrading to Polyboard. Polyboard integrates seamlessly

with Biesseworks and Biessenest. It produces an special file that will allow automatic import of all parts from Polyboard to Biessnest.

All you have to do is select the sheet to nest on and away it goes these is no need to set-up and toolpathing in Biessworks as all data

is transfered from Polyboard. In addition at the same time as importing all the parts themselves part data such as job name, part name

cabinet name and edgebanding location are all transfered so that part sticker labels can be printed in Biesse labels just as before.

So if you are a Biesse owner who is still using the spreadsheet what are you waiting for? Call us for an on-site or on-line demo of

Polyboard to see how it will increase your productivity and design ability. This is main the reason why we started promoting this range

of software applications, as before we offered Polyboard there was very little choice when it come to quality software with real design

ability. The few good applications that were available were almost the same cost as the CNC machine itself! Polyboard’s success has

been because it enables the user to have access to powerful industry leading technology at extremely affordable price. if you haven’t

already done so please go our Polyboard page for more information or the online ordering section to see the the incredible price for this

very special software application.

March 2013

Focus on Polyboard and Optinest for nesting CNC Owners (Part 2)

This month we will take a look at he benefits and reasons why a company should switch to a dedicated nesting application rather on

rely on the stock nesting utility that was bundled with your machine. As we discussed last month many manufactures and also

standard cam software packages include basic nesting feature. The features vary, but the basic requirement is that they have is to be

able to import parts automatically taking notice parameters of parts such as quantity, grain information and other descriptive

information about cabinet a job that the parts belong to that can be included in part labeling. While most application can do this and

then take the parts and arrange them in a nested sheet., the nested arrangement and other advanced features such as part labelling,

and off-cut management, either are non-existent or leave a lot to be desired. So to promote the benefits of switching to a real true

shape nesting application we present the following 5 Points:

•

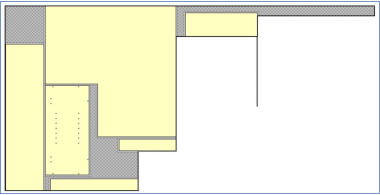

1) Better Nesting Calculation Algorithm: Optinest will give you a tighter

nest this will not only save you material but it will also allow you to have less

sheet loading and unloading cycles and both of these factors will save you

money both in material and labour. A test comparison we conducted

recently where an average size kitchen white board parts used 20 x 2.4 x

1.2 sheets whereas Optinest nested the same parts onto just 19 sheets.

And this was with rectangular parts. if you have curved parts Optinest will

do significantly better the the stock nesting programs. Remember if you are

processing 40 to 60 sheets a day that means it will save you 2-3 sheets and

20-30 minutes of time each day. We had a case last year where a

commercial furniture manufacturer needed to fit 3 x 120 degree workstation

tops onto a 3600 x 1800 board. they switched to Optinest after the standard

programs they had could not make the 3 tops fit even though they

physically could!

•

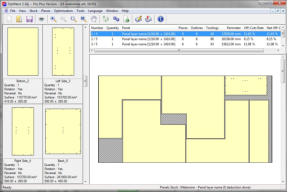

2) Seamless transfer of parts from Polyboard: One of the great features of purchasing our Nesting Pack is the seamless

transfer of parts from Polyboard to Optinest. in one click Optinest is started and instantly all parts are loaded. parts are sorted

by material and they are all loaded within separate windows ready for nesting each material that is used. Even if you want to

use another design application Optinest can be driven from the command line so that you can have your other design

application remote start and load your nesting job instantly.

•

3) Easy and comprehensive part labelling:

Optinest has part labelling built in as standard.

labels cab be configured to show part

descriptions such as part, cabinet and job names

as well as other user text such as your company

name. A part graphic showing the part shape and

machining can be printed alongside.

Edgebanding location and edging description

(type and thickness) for the four principal sides is

shown graphically along the edges of the label

enabling edge-bander operators to see visually

which side of the part they need to edge. which what edge. Labels can be printed from dedicated label printers or on standard

Avery type sheet labels, with a mechanism to allow you to use the full sheets. In addition to part labels Optinest can also be set

to print labels for reusable offcuts

•

4) Advanced Offcuts reuse and management:

Optinest really stands out when it comes to off-cut

reuse. While few nesting packages even offer a

feature, Optinest does it well. The off-cut management

system allows you to specify the minimum area that is

considered reusable and save the shape for reuse on

the next job. For example one useful feature is that

when nesting you can set-up Optinest to place pieces

first on the right hand side of the board so that any off-

cut that results will still have 90 degree edges on the

left edge. this will enable you to easily place the offcuts

up against the machine origin stops on the left side

when you come to use it. As well as recovering the off-

cut and nesting new parts on it. Optinest gives you the

option to keep track of stocks so that you can specify

the number of sheets you have in stock and after nesting once click of the ‘deduct panels’ button will both subtract the sheets

used from the stock level and also add in the reusable offcuts. ready for your next nesting job.

•

5) Cost effective pricing. As with all of our software we strive to provide top class solutions with advanced solutions that even

the packages costing many times the price of our software struggle to include. Optinest tooling version includes all of the

features that we have discussed here and more. to see our current pricing click through to our on-line ordering store.

April 2013

Special offer on Optinest Pro-Plus version!

Following on from last months introduction into the benefits of switching to our nesting program Optinest we have a special deal on the

top of the line Optinest Pro-Plus version.

This version gives you access to all the features that cabinet makers need:

•

seamless integration cabinet design software,

•

Advanced part labelling

•

nesting on to offcuts for efficient reuse

For the month of April until the first week in May we are offering a massive 20% off the list price. So to qualify for this great offer you need

to contact us and pace your order before then!

BLOG | Newsletters | FAQ | Testimonials | Videos | Polyboard | Optinest | Opticut | Wardrobes | Kitchens | Office fitouts | Contact

July 2013

Polyboard Version 5 released!

This month we are really excited to announce that the latest version of Polyboard version 5 has finally become available as a first

finalised version. Although many customers have already been enjoying a lot of Polyboard 5’s new features in Pre-release, this marks the

culmination of a lot of new features added. As Is the Polyboard way there are no ongoing “service” or maintenance fees for our software

but when a new version is released there is a fee for upgrading. Below we aim to list all of the new features since version 4 so the

decision to upgrade for all of our existing version 4 customers will be simple and easy!

New features in Projects and 3d layouts.

1.

Project view dimensioning - Project views now have cabinet dimensions automatically added. and can be turned off.

2.

Project partial views - Ability to set cut-planes in the 3d space to get clear shop drawings without other cabinets in the 3d space

blocking the view, ability to set multiple cut-planes and also to name them. this feature generated excellent shop drawings in 2d or

3d and can even generate cutaway sections of cabinets.

3.

Measuring tool - ability to check distance between cabinets and cabinets and walls in 2d or 3d also has ability to convert

measurements into fixed drawing dimensions.

4.

New window interface for creating floors and walls - ability to created rectangular floors very efficiently.

5.

New features to create bench-tops, and counter-tops. to go over cabinets

6.

Ability to set default cabinet height z value easy bring in wall cabinets and base cabinets directly to correct location and heights.

New features in Cabinet editing and design:

1.

New exploded view feature - see hardware machining on panels in the design view window. new exploded view visuals.

2.

New inner-casings parts - ability to ad a stopped shelf and upright to crated a inner space in a couple of clicks similar to the un-

boxing to create the external cabinet void.

3.

ability to set hardware fittings between surface splits or parallel panels - allows for the creation of blind corner cabinets or bi-fold

doors very easily and with full para-metrics.

4.

Free shape designer window has been extended to allow multiple coordinate systems

5.

Part over-sizing parameters can be set individually on each part.

6.

Ability to automatically bring in drawer parts from a manufacturing method.

7.

Ability to set an overall cabinet upper strip/ bulkhead area height and kick board/plinth elevation/height.

8.

Edges between double doors update with application edging methods

9.

Ability to set a inner-tooling material while having the over all part set to nil.

New General Features:

1.

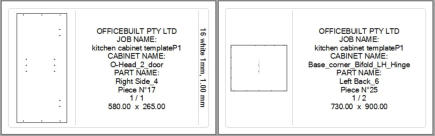

New catalogue mode: allows Polyboard to process cabinets like a cabinet pricing spreadsheet exporting cabinet multiples to cnc

post-processor and cut-lists with tallied up clear costings.

2.

new cut-list options to export multiple cabinets and synchronised part numbers between cultist and cnc post processor export.

3.

New cabinet multiple view on one page drawings - can be user set any combination of top side bottom and various 3d perspective

drawings on one page.

4.

Ability to print part labels directly in Polyboard.

5.

New Post-processor for the automatic transfer of parts to Optinest

6.

Post-processor exports real arcs instead of poly-lines giving smother running machines and curves.

7.

Import/export of Post processors and hardware fittings

8.

Ability to merge opposite side drilling’s into through drills for nesting or preserve sides for PTPs.

9.

Automatic part rotation for over height parts fro PTPs.

So as is clear there are a lot of new features on offer for Polyboard 4 users to upgrade, and of course there has never been a better time

for new users to join the growing list of satisfied Polyboard customers!

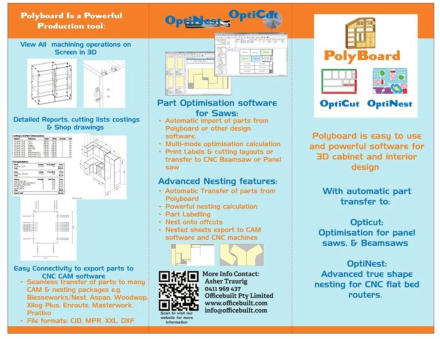

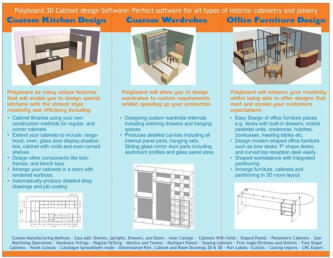

September 2013

New Product Literature

We are exited to launch a new marketing campaign to

promote Polyboard cabinet design awareness over

the next few months. In supporting this campaign we

are launching two new documents on that outlines the

main benefits and features that Polyboard interior

design / cabinet design software offers and to

complement i we have also produced a new glossy

printed brochure, that not only summarises these

features, but also highlights the recent industry

specific web pages that we designed. We hope that

these new materials will give people in the industry

out there clear ideas about just how practical and

useful Polyboard is.

If you would like to receive these printed

materials in the mail please contact us with your

address and we will be happy to post them out to

you. Also as added incentive for people to sign

up for our newsletter we are offering a free

Polyboard branded 2GB USB thumb drive to new

subscribers. if you would like to receive yours all

you have to do is sign up and confirm your email

on our automated newsletter system and then

email us your mailing address and we

will post one of them out to

you. But please

hurry this

offer is

limited to the

first 50 new

subscribers!

October 2013

Polyboard to Aspan Connection Successful!

Over the last few months we have welcomed a new customer to the Polyboard users group 3D cabinet concepts of Cabouture QLD.

they are a 3rd party manufacturer where cabinet makers in the local area can ced parts made and painted all in a one stop shop. see

their facebook page at: https://www.facebook.com/3dCabinetConcepts

While they have been servicing their customers using their trusty Anderson Nesting machine together with a custom spreadsheet

application linked in with Aspan for generating machining code. While this spreadsheet works well for simple requirements they

looked to Polyboard to provide them with a full featured 3d Design and drawing package in order to keep up with their customers

demanding requirements.

We found that Polyboard linked in well with Aspan using the flexible dxf post-processor built in and before long 3d cabinet concepts

were able to get quite a few jobs out the door using Polyboard as the new design tool.

As with Biessenest, Polyboard is able to export a csv import file that includes all the part data about each of the individual parts in a

job so that when you come to the nesting interface in Aspan you just select the import file and Aspan takes care of the rest: imports

all the files, assigns the correct quantity and grain direction of each part, as well as passing general information about each part

though to the label generator. All in all Aspan becomes like a ‘black box’ through which all the exported parts from Polyboard are

exported and then Aspan automatically nests and generates machine gcode

As usual there is still the option to go via Optinest, Polyboard links in seamlessly to Optinest so if you want to take advantage of

Optinest superior nesting capabilities, then you can still use this option and then send your competed nested sheets to Cam software

like: Aspan, Biesseworks or Enroute

So if you are a user of an Anderson CNC router or a long faithful Aspan user get in touch with us as we now have extensive

experience in linking Polyboard to Aspan!

December 2013

New industry Page: Interior fitouts

This month we have completed the latest in our series of industry pages. The aim of

these web pages is to highlight how our software has capabilities in each specific area in

order to effectively service these industries. We present the key features that are built in

to our software programs that are necessary and commonly used in these industries.

This month saw the completion of the interior fit-outs. to highlight the effectiveness of

Polyboard in interior design we present a real job created in Polyboard and the n built for

a customer. As you can see the picture in Polyboard compared to the actual photograph

of the completed job.

This particular design utilises many of Polyboard’s special features for example

it has an ‘unboxing’ on the to left corner, An ‘unboxing’ is used where the cabinet

had to fit around an internal duct and protruding wall vent Polyboard easily

calculated the parts to fit around this building feature in a few clicks including all

cam and screw fitting hardware. Other features to note are the top central cut-

outs in the back panel to allow the wall mounted air-conditioning outlet to be

routed through the cabinet.

This design also highlights several standard modern cabinet features include:

push to open doors, overlay sliding doors, central dividing panels with double

sided face cams, and hinged kick panels.

look out for our next industry page shop fitouts early in 2014!