Contact Us: 0411 969 437

OptiCut sheet

optimisation for panel

and Beamsaws &

crosscut profile saws

The software Is a

powerful and

competitively priced

package that is feature

packed and includes

direct connection to

most CNC saws.

Optimisation Features:

Opticut Is based on a powerful Algorithm with 6

predefined optimisation modes

The algorithm can also take into account machine

features so that the optimisation will reflect

capabilities of your machine

Depending on the optimisation mode, the panels

turnaround feature can be turned on to increase

material yield or off to reduce cutting times and

manual panel handling.

There is control over many aspects of the

optimisation and settings related to particular

machines can also be configured.

Optimisations can be run over multiple materials

types and sheet sizes simultaneously.

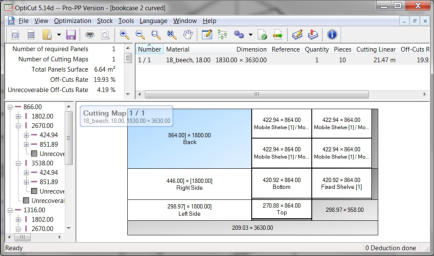

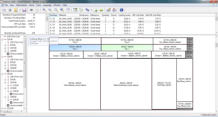

Optimisation results are

presented in an easy

format that displays the

panels required a report on

the pieces placed /not

placed and edging

information if required..

Connectivity:

Opticut can import part lists and files

from many design applications in

the CSV format. The built-in import

configuration allows the program to

adapt and import files from any

spreadsheet and most design

applications

Direct and seamless

import of part

files from our

own design

Application

Polyboard.

Opticut has a universal Post- processor

that can translate the optimised

cutting layouts into the main CNC

saws languages and formats.

Bars / linear Lengths:

In addition to panels Opticut can also

optimise Linear Bar materials.

Opticut can take into account angles

and section symmetries and will

therefore calculate an optimised

cutting patterns

3D views of section can be seen

showing exactly how cuts will be

made. Using the dxf format section

drawing can be loaded and

associated with particular profiles.

In a similar way to panel materials

Opticut also maintains a library of

profile materials with current stocks

and offcuts tracking.

Reports & Printouts:

Full reports including cutting lists,

materials lists, and optimisation

results lists can be all printed.

The reports can be customised by

turning on or off features and list to

be printed. Full sets of cutting maps

for both panels and profiles can be

printed

Opticut can also generate part labels

with full customisation of the label

information fields.

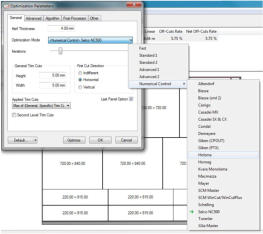

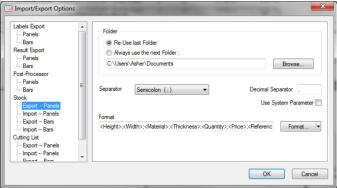

Setting

optimisation

parameters

gives

maximum

flexibility over

the resulting

layout to let

you cut the

way you want

←

Optimisation mode can be set to universal or specific

requirements of a numeric controlled saw.

↓

Optimisation results window

Setting

optimisation

parameters

gives

maximum

flexibility over

the resulting

layout to let

you cut the

way you want

←

Choose between sheet

or bar type optimisation

project

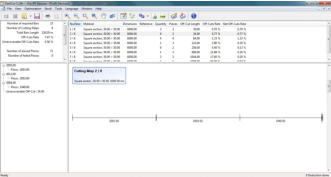

Detailed optimised linear bar results

Clear 3D drawings of profiles

showing angle cuts

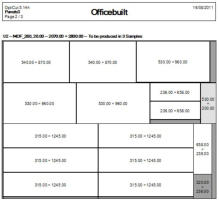

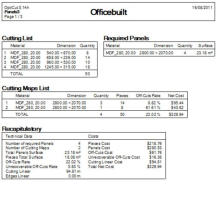

Printed reports including

cut lists , full sheets ,

optimisation results and

detailed cost itemisation

←

Printed bar optimisation

cutting layout / diagrams

Printed sheet cuting

layout / digram →

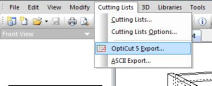

Fully configurable import export of cut-lists

↓

Easy transfer of parts from

Polyboard to Opticut

Export optimised cut-maps to most CNC

machines

↓

BLOG | Newsletters | FAQ | Testimonials | Videos | Polyboard | Optinest | Opticut | Wardrobes | Kitchens | Office fitouts | Contact