Contact Us: 0411 969 437

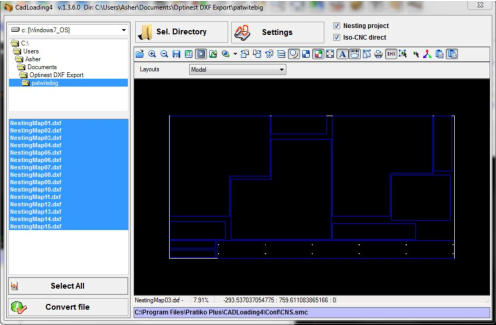

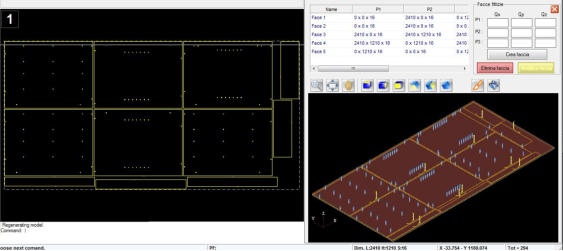

Pratiko CAM software

Powerful tool-pathing software for all CNC woodworking machines. Whether you run Point to Point, Pod and Rail, or Flatbed - nesting machinery our cam software will help you run your machine efficiently & easily!

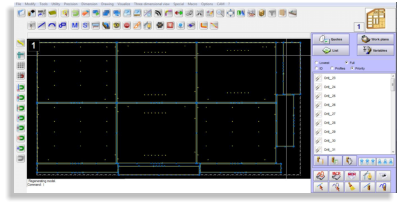

CAM features:

•

Full dxf file import features -

individually or as a batch

•

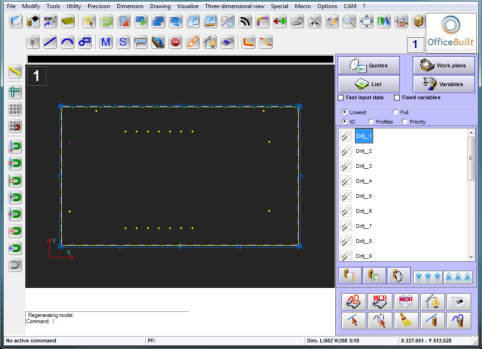

Easy Automatic tool-path

configuration utility assign tool-

pathing strategies to dxf layers to

automatic tool-path on import.

•

Automatic toolpath for inside and

outside router offsets, vertical and

horizontal boring, grooving saws,

& pocketing for closed profiles.

•

Window for manual assigning of

tool-paths strategy to imported

profiles.

•

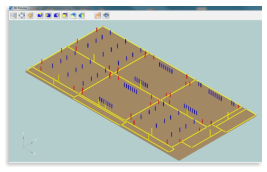

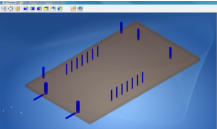

Visualise tool-path, tool direction,

tool diameter, cutter

compensation all in 3d on screen.

•

Automatic optimisation of drilling

and drill banks

•

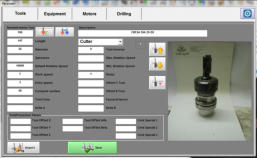

Complete technology and tool database. Set-up drill head

configuration, router heads and tools, automatic tool

changers.

•

Gcode generation for all cnc machines.

CAD Drawing features:

•

Full set of cad drawing tools

available.

•

draw all standard shapes eg lines

arcs , rectangles , circles ellipses

splines with complete set of snap

point options.

•

Drawing entity modification tools

included, i.e. measuring tools,

profile offset, profile direction

control, corner radius etc..

•

Built in window macros to easily

program all available tools, i.e.

Drill banks, routers, grooving saws

•

Powerful pocketing algorithm

•

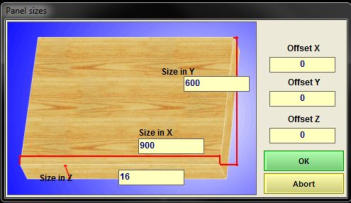

Full parametric programming

system; - use built in system

variable for part dimensions in

addition to user defined variables.

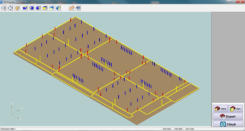

Nesting and single part special

Toolpathing Features:

• For single part processing our cam solution includes special features such as horizontal boring on all faces, and batch processing.. • Our cam also has specific nesting related tool-pathing features including configurable angle tool lead-in / lead-out to prolong tool life and reduce part damage on entry and exit • Configurable ‘onion skinning’ two pass router tool path to reduce part movement during processing • Setting priority of tools / and or processes also to minimise part shifting during the part separation phase. • Couple our highly regarded nesting optimisation software Optinest together with our Pratiko cam solution to obtain extremely low material wastage together with efficient ready to run G-code on your CNC machine!

BLOG | Newsletters | FAQ | Testimonials | Videos | Polyboard | Optinest | Opticut | Wardrobes | Kitchens | Office fitouts | Contact