Contact Us: 0411 969 437

Polyboard is a unique & powerful tool for standard

furniture ranges and custom fitouts. In the

Office furniture industry Polyboard allows you

to quickly and easily customise office fitouts.

Unlike other software packages that are based on

fixed cabinet libraries, Polyboard gives you the

full control over the manufacturing and

construction process allowing you to create

designer furniture to any specifications.

Polyboard does it all: Great on-screen display

graphics, full control over design and the

ability to export 100% of your design to a CNC

machine with complex part shaping, boring,

cut-outs and other machining - all in 3D with

100% accurate costings for each component

right down to the last screw!

Easily design standard office

furniture

Standard office furniture is a breeze with Polyboard!

Easily create desks credenzas hutches returns,

bookcases and meeting tables in next to no time

Polyboard allows you to define furniture styles and

manufacturing methods that will allow you to

create furniture pieces from scratch very quickly,

or if you prefer to work form a standard library of

items You build one piece say a desk or

bookcase, duplicate it, make changes and watch

you’re own personalised furniture library grow in

next to no time!

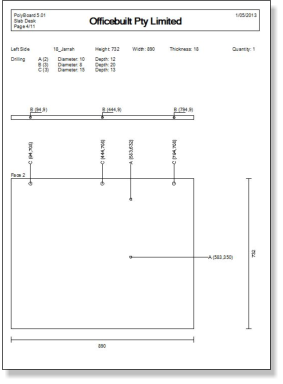

Easy design your machining and drilling

requirements. Polyboard has fully parametric

hardware generation no matter what brand fitting

or type Polyboard can set it all up automatically.

Polyboard can easily define hardware such a

edge-boring cams, face bored cams or even fixing

screws. Hinges can be set up to be match the

drilling configuration of any hardware supplier such as

Hettich, Blum, Grass etc..

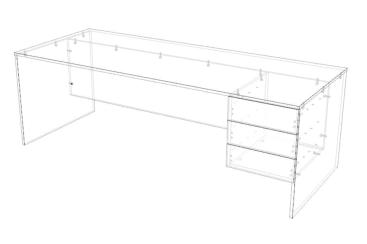

↓ Desks are easily designed in

Polyboard complete with built in

drawer boxes!

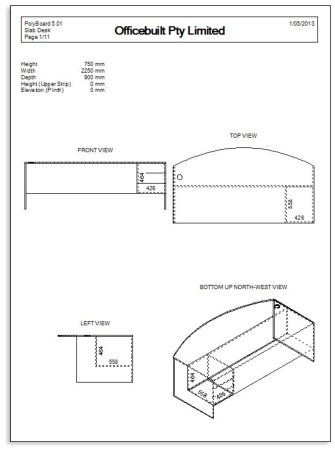

↑ Credenzas with or without hutches can be designed and all

drilling and machining is easily viewable on screen.

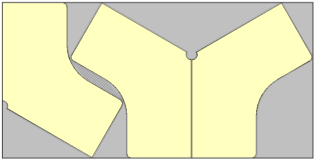

Curved and shaped office furniture:

Polyboard offers easy methods for shaping furniture and parts easily create shaped office furnishings such as: o Curved front desks o ‘P’ - shaped desks o Workstations with ‘natural’ work curves o shaped cut-outs for cabling and power point connections o Reception desks with multiple panel fronts and curved side panels. Once these furniture items are designed. they remain fully parametric, which means, even though they have complex shapes that you can still reuse the design for subsequent jobs by duplicating and modifying the overall dimensions to use design and shape but with different overall dimensions.

Polyboard

Produces detailed

part drawings →

Design office layouts and

present them to customers

in both 3D rendered as well

as fully dimensioned plan

drawings.

Detailed job costings

↑ Bookcases and meeting tables whether they are square or

rounded can be designed and manufactured. Furniture is

beautifully rendered on screen prior to production.

Polyboard gives you the freedom

to design and be creative in

furniture production easily create

curved products such as bow front

desks and meeting table desks.

Reception desks with

multiple sides such as

this unit with 6 sides

are easily designed in

Polyboard.

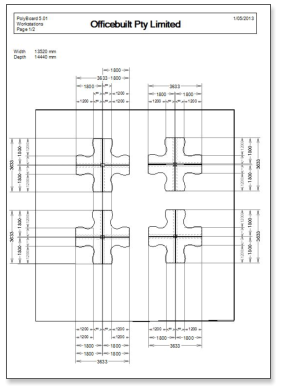

↑ Workstations with complex shapes are easily

modeled and manufactured in Polyboard.

↑ Polyboard automatically produces

multiple view drawings of all your

designed items. with views fully

customisable.

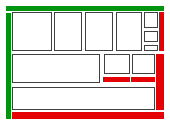

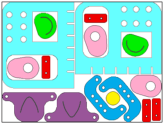

120 Degree workstation tops nested into a single

3.6 x 1.8 sheet by Optinest!

BLOG | Newsletters | FAQ | Testimonials | Videos | Polyboard | Optinest | Opticut | Wardrobes | Kitchens | Office fitouts | Contact

Office layout part drawings &

renderings :

Polyboard produces nice 3d rendered graphics

that will demonstrate your office fit-outs to your

customers, with full rotation and zoom

controls.

In addition to 3 dimensional rendered views,

manufacturing plans and dimensioned

drawings are also able to be generated.

Multiple view drawings of furniture items or

complete office layouts are automatically

produced as well as detail individual part

drawings showing all machining requirements.

When design office layouts, Polyboard also gives

you the option of adding in your own

dimensions to show special features of your

designs i.e. space between cupboard and

doorway or space between a cupboard and a

desk to show that there is adequate space to

open doors, and move chairs about.

Parts can be made semi-transparent to show

cabinet internals and there is also a feature to

animate the opening and sliding of doors and

drawers.

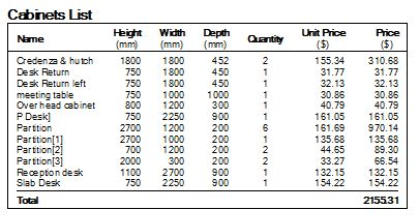

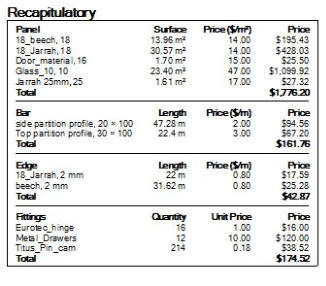

Reports and Detailed Job

Costing:

In Polyboard the ability to generated detailed

costing reports comes as standard. This feature

itemises all the components and materials that go

into your fit-out. The reports will help you with both

understanding the cost of your job so you are able

to quote properly, but it will also assist you in the

ordering of components from suppliers for each job.

o

All panel materials have a cost / square

metre and thereby Polyboard calculates

total cost for each material used including

surface laminates like those applied to

kick-boards.

o

Edgebanding is costed by the metre and

total edgebanding used for each type of

tape is calculated and added up.

o

All hardware fittings are totalled and

costed separately giving you accurate

both knowledge of what items are in each

job, and the total cost. all items are

included; adjustable shelf support pins,

hinges, drawer runners / sides, as well as

pins and cams.

Polyboard Also will generate a report that will

itemise all the cabinets used in a job. that would be

useful to be use as a truck loading list or even for

general quoting purposes.

Production add-ons and

Machine connectivity:

Polyboard in addition to the detailed printed reports

Has a very powerful machine post processor. The

post processor is able to produce customised

machining files in a variety of formats: dxf, CID,

XXL, MPR files of all parts. these part files can be

imported by virtually all machines and cam

packages.

While Polyboard can integrate well and connect

easily to third party Sheet optimisers nesting

software and cam software. Users of Polyboard also

have the opportunity to upgrade to our own Nesting

and saw optimisation software Optinest and Opticut.

Having your optimisation software come form a

software export will not only give you better

optimisation results (and money saved) but will give

you loads of extra features that third parts add on

software simply can’t match.

So no matter weather you produce your fit-outs

using panel-saws, beams saws and Point to point

cnc machines or you use the nested based

manufacturing method our range of add-on software

will connect seamlessly to your machine. and have

you working very efficiently.